- Graphtec Cutting FC9000

GRAPHTEC CUTTING PRO FC9000

World's best quality and strengthened functions

High-end model with its performance improved

and best-in-class performance/quality inherited from former models.

Highest Level Performances

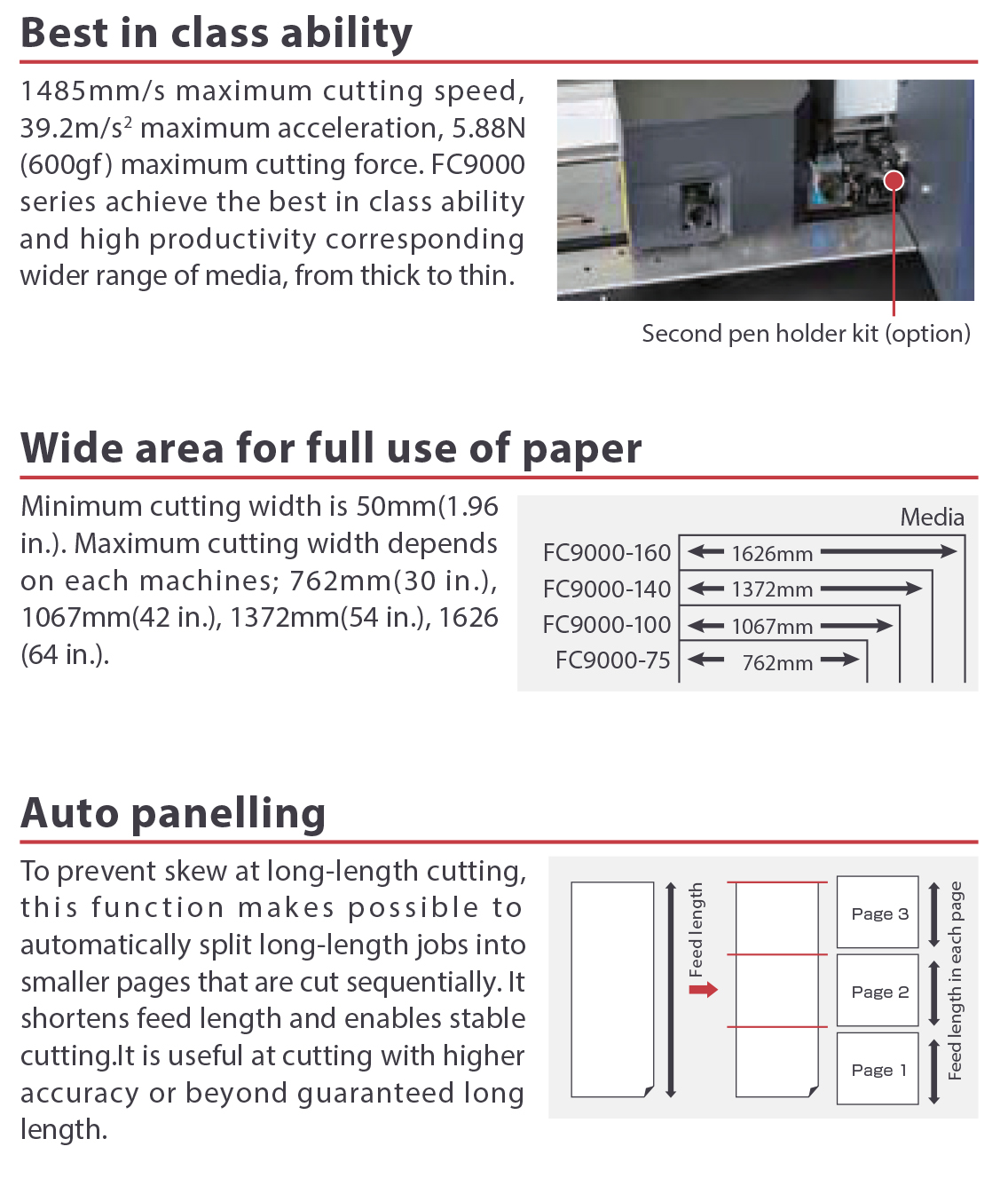

Best in class ability

1485mm/s maximum cutting speed,

39.2m/s2 maximum acceleration, 5.88N

(600gf ) maximum cutting force. FC9000

series achieve the best in class ability

and high productivity corresponding

wider range of media, from thick to thin.

Wide area for full use of paper

Minimum cutting width is 50mm(1.96

in.). Maximum cutting width depends

on each machines; 762mm(30 in.),

1067mm(42 in.), 1372mm(54 in.), 1626

(64 in.).

Auto panelling

To prevent skew at long-length cutting,

t h i s f u n c tion makes possible to

automatically split long-length jobs into

smaller pages that are cut sequentially. It

shortens feed length and enables stable

cutting.It is useful at cutting with higher

accuracy or beyond guaranteed long

length.

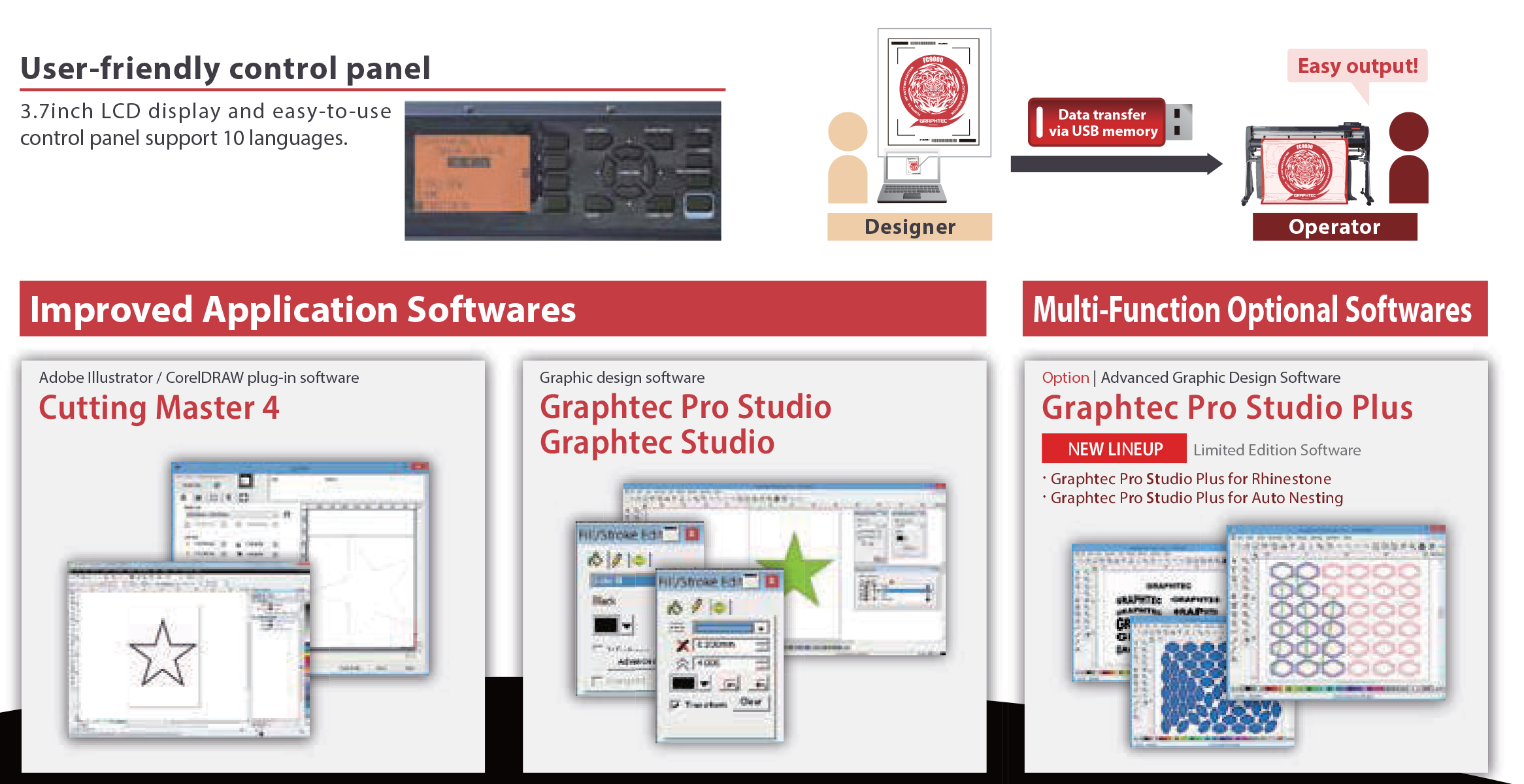

User-friendly control panel

3.7inch LCD display and easy-to-use

control panel support 10 languages.

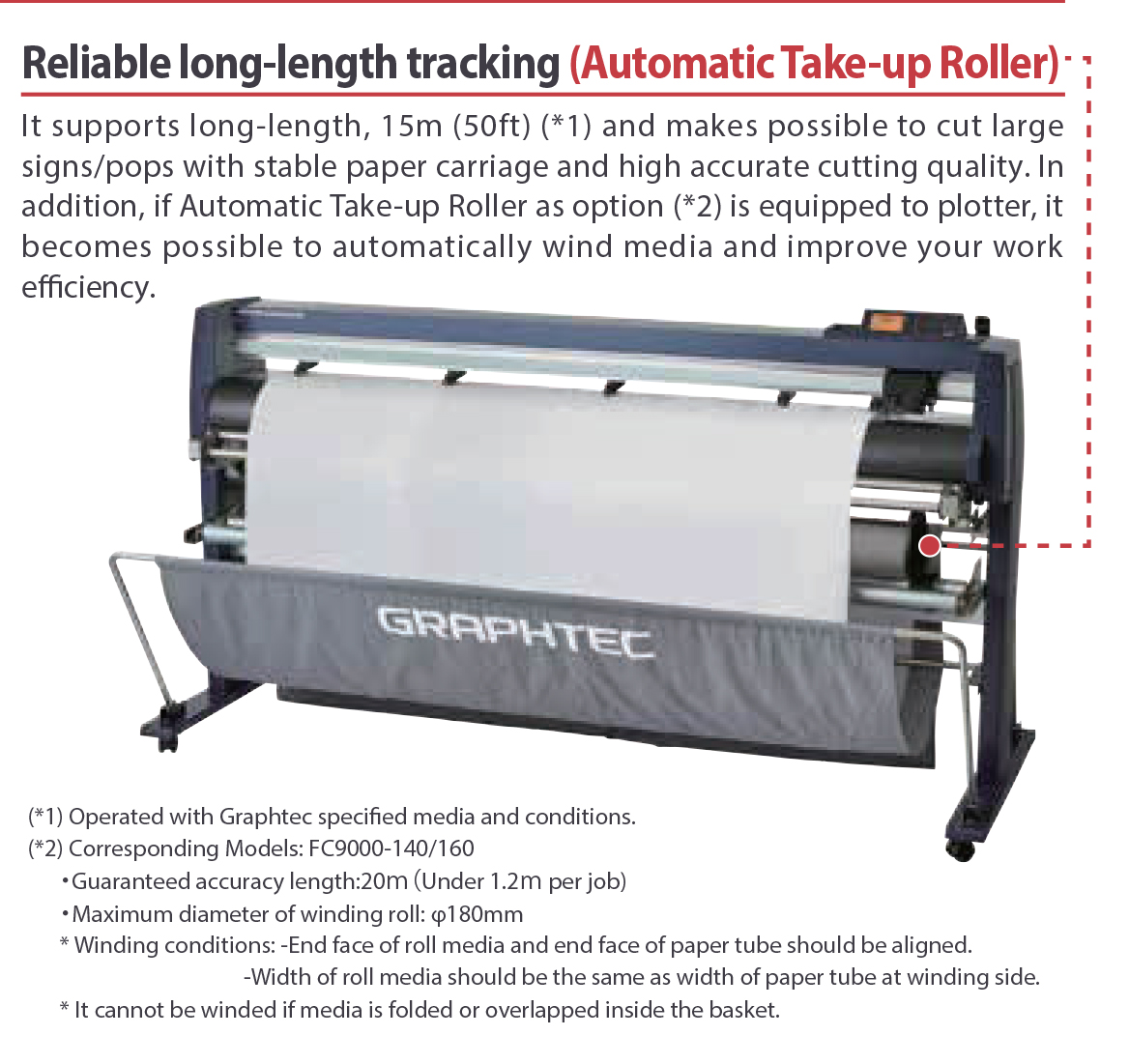

Reliable long-length tracking (Automatic Take-up Roller)

It supports long-length, 15m (50ft) (*1) and makes possible to cut large

signs/pops with stable paper carriage and high accurate cutting quality. In

addition, if Automatic Take-up Roller as option (*2) is equipped to plotter, it

becomes possible to automatically wind media and improve your work

efficiency.

Improved Application Softwares

Adobe Illustrator / CorelDRAW plug-in software

Cutting Master 4

Graphic design software

Graphtec Pro Studio

Graphtec Studio

Multi-Function Optional Softwares

Graphtec Pro Studio Plus

Improved ARMS for high precision cutting ARMS 8.0

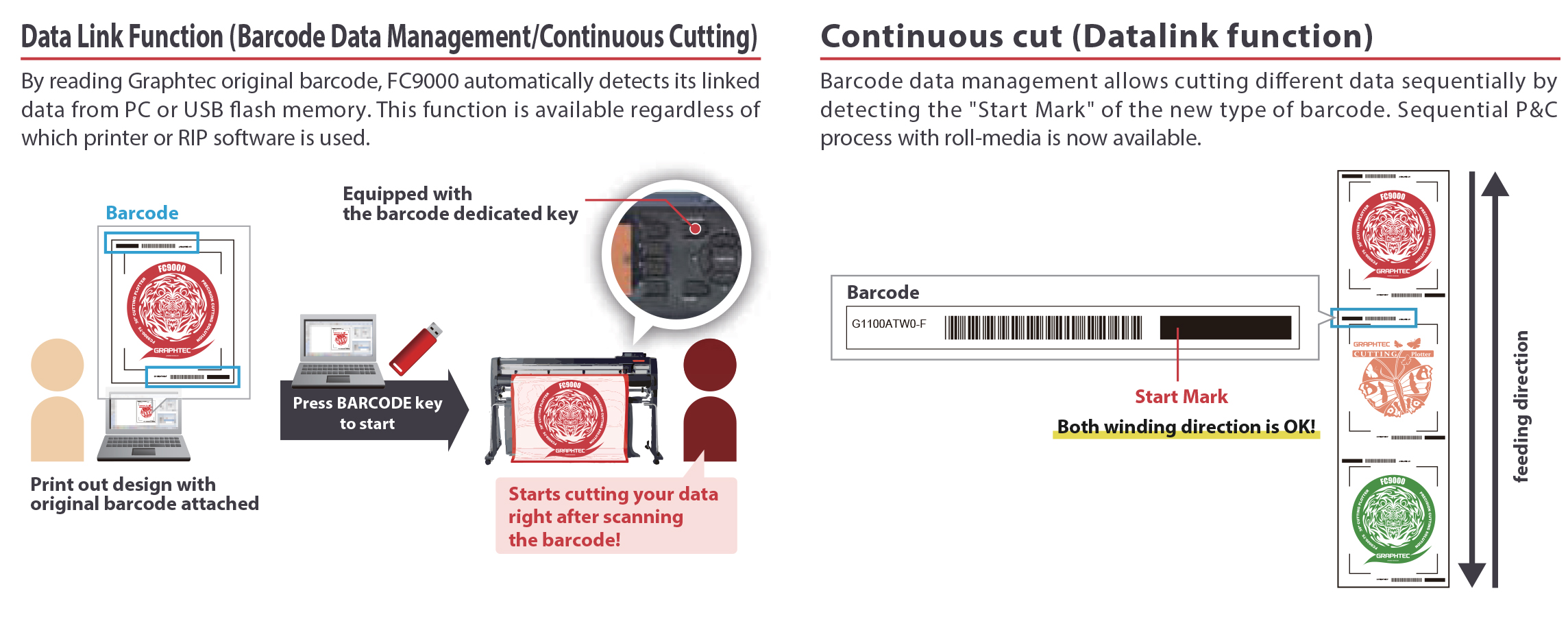

Data Link Function (Barcode Data Management/Continuous Cutting)

By reading Graphtec original barcode, FC9000 automatically detects its linked

data from PC or USB flash memory. This function is available regardless of

which printer or RIP software is used.

Continuous cut (Datalink function)

Barcode data management allows cutting different data sequentially by

detecting the "Start Mark" of the new type of barcode. Sequential P&C

process with roll-media is now available.

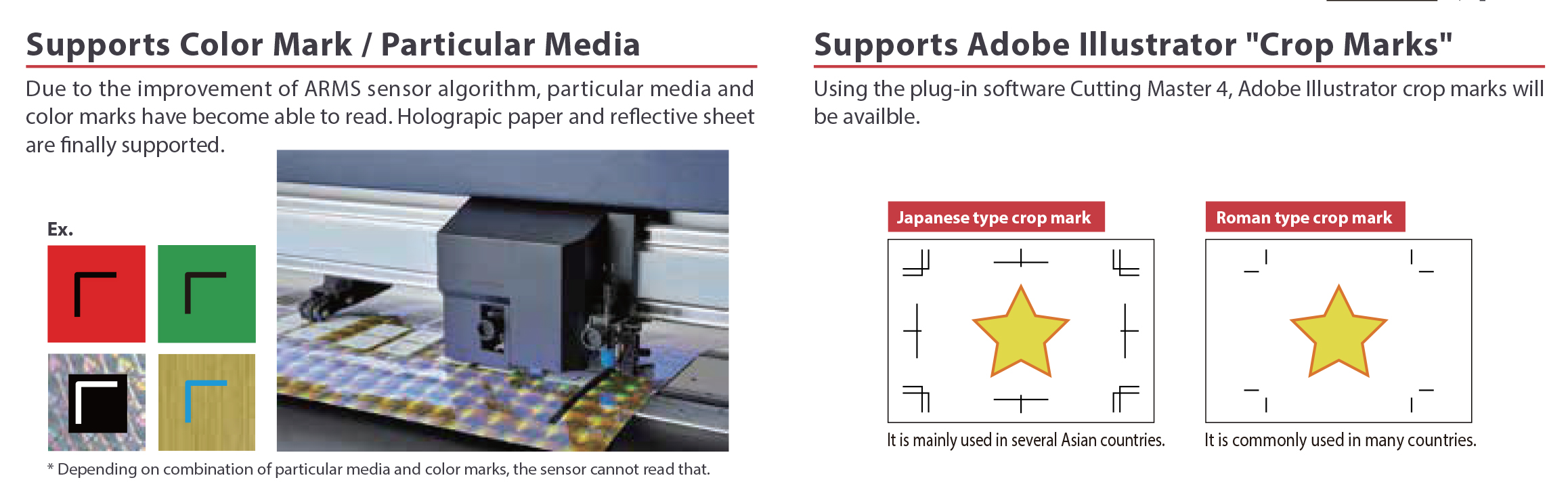

Supports Color Mark / Particular Media

Due to the improvement of ARMS sensor algorithm, particular media and

color marks have become able to read. Holograpic paper and reflective sheet

are finally supported.

Supports Adobe Illustrator "Crop Marks"

Using the plug-in software Cutting Master 4, Adobe Illustrator crop marks will

be availble.

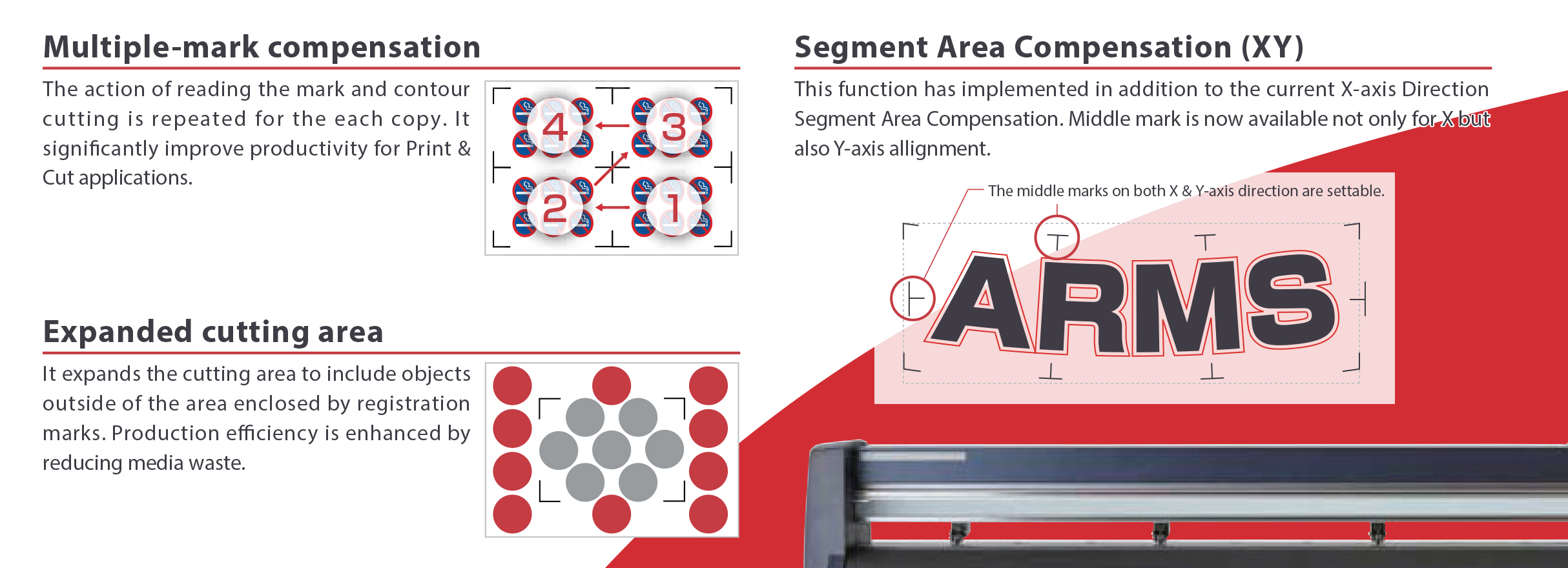

Multiple-mark compensation

The action of reading the mark and contour

cutting is repeated for the each copy. I t

significantly improve productivity for Print &

Cut applications.

Segment Area Compensation (XY)

This function has implemented in addition to the current X-axis Direction

noe Segment Area Compensation. Middle mark is now available not only for X but

also Y-axis allignment.

Expanded cutting area

It expands the cutting area to include objects

outside of the area enclosed by registration

marks. Production efficiency is enhanced by

reducing media waste.

| Model | FC9000-75 | FC9000-100 | FC9000-140 | FC9000-160 |

|---|---|---|---|---|

| CPU | 32-bit CPU | |||

| Configuration | Grit rolling plotter | |||

| Drive method | Digital servo drive | |||

| Max. cutting speed | 58.5 inches per second (45 degree direction) 41.3 (axis direction) | |||

| Cutting force | Max. 600 gf in 48 steps | |||

| Axial acceleration | Max. 39.2 m/s2 (4 G) in 8 steps | |||

| Max. cutting area (W x L) (*1) | 30 in x 164 ft 762 mm x 50 m | 42 in x 164 ft 1067 mm x 50 m | 54 in x 164 ft 1372 mm x 50 m | 64 in x 164 ft 1626 mm x 50 m |

| Guaranteed precision cutting area (*1) | 29.21 in x 50 ft | 41 in x 32 ft, 35.2 in x 50 ft | 53 in x 32 ft, 35.2 in x 50 ft | 63 in x 32 ft, 35.2 in x 50 ft |

| Mountable media width(*2) | Min. 1.96 in | Min. 1.96 in | Min. 1.96 in | Min. 1.96 in |

| Max. cross cut width | 30 in | 42 in | 54 in | 64 in |

| Number of push rollers | 2 rollers | 3 rollers | 4 rollers | 4 rollers |

| Compatible roll media diameter | Min. 2.99 in Max 7.8 in. (Max diameter is 6.29 in when included flange is installed) | |||

| Mechanical resolution | 0.005 mm | |||

| Programmable resolution | GP-GL: 0.1 / 0.05 / 0.025 / 0.01 mm, HP-GL™: 0.025 mm | |||

| Distance accuracy (*2) | Max. 0.1 mm or 0.1 % of plotted length | |||

| Repeatability (*2) | Max. 0.1 mm in plot up to 2 m (excluding the expansion and contraction of the media) | |||

| Minimum character size | Approx. 5 mm alphanumeric (varies depending on character font and media) | |||

| Mountable number of tools | 1 tool (cutting blade, plotting pen or pouncing tool) in standard; 2 tools (cutting blade and plotting pen) when second penholder (optional) is installed | |||

| Blade types | Supersteel (0.9 mm or 1.5 mm diameter) | |||

| Pen types | Water-based fiber-tip pen, Oil-based ballpoint pen | |||

| Pouncing tool type | Steel pin 1.2 mm diameter, required optional pouncing tool (PPA 33-TP12) | |||

| Media types (*3) | Self-adhesive marking film (vinyl, fluorescent, reflective, high-intensity reflective film) up to 0.25 mm thick, Sandblast resist rubber up to 1 mm thick | |||

| Compatible paper for pouncing | Regular paper from 0.06 to 0.13 mm thick | |||

| Cross-cutter | Built into the tool carriage | |||

| Perforation cutting | Supported (performed by force control) | |||

| Interface | USB 2.0(Full Speed), Ethernet 10BASE-T/100BASE-TX | |||

| Buffer memory | 2 MB | |||

| Command sets | GP-GL / HP-GL™ emulation (Set by menu or command, and selects from GP-GL, HP-GL™, or Auto select) | |||

| Condition settings | Dual configuration (save two (2) user settings with eight (8) separate condition settings per user) | |||

| Display | Graphic type LCD (3.7-inch, backlight) | |||

| Power source | 100 V to 240 V AC, 50 / 60 Hz | |||

| Power consumption | AC100-240 V, 50/60 Hz | |||

| Operating environment | 50 to 95 ºF, 35 to 75 % R.H. (non-condensing) | |||

| Guaranteed accuracy environment | 60 to 89 ºF, 35 to 70 % R.H. (non-condensing) | |||

| External dimensions (W x D x H) | Approx. 50" x 28" x 48" (1270 x 711 x 1219 mm) | Approx. 61.8" x 28" x 48" (1570 x 715 x 1219 mm) | Approx. 73.6" x 28" x 48" (1870 x 711 x 1219 mm) | Approx. 84" x 28" x 48" (2130 x 711 x 1219 mm) |

| Weight (*8) | 108 lbs. | 123 lbs. | 141 lbs. 178 lbs. /w take-up | 154 lbs. 195 lbs. /w take-up |

| Included software (*6) | Windows Driver, Graphtec Pro Studio (*5), Cutting Master 4, Graphtec Studio for Mac | |||

| Compatible OS (*5) | Windows 10 / 8.1 / 7 Mac OS X 10.6 to 10.11 Mac OS 10.12 to 1.14 Graphtec Studio: 10.6 to 10.14 Cutting Master 4: 10.7-10.14 | |||

| Safety | PSE, UL/cUL, CE mark) | |||

| EMC | VCCI Class A, FCC Class A, CE mark | |||

คุณคณธัช 093-139-9877, คุณศิริพร 081-376-7411, คุณจูน 089-448-5326

คุณปลา 084-296-6481, คุณพีซ 094-624-4747

หรือกรอกแบบฟอร์มติดต่อกลับด้านล่างได้เลยครับ